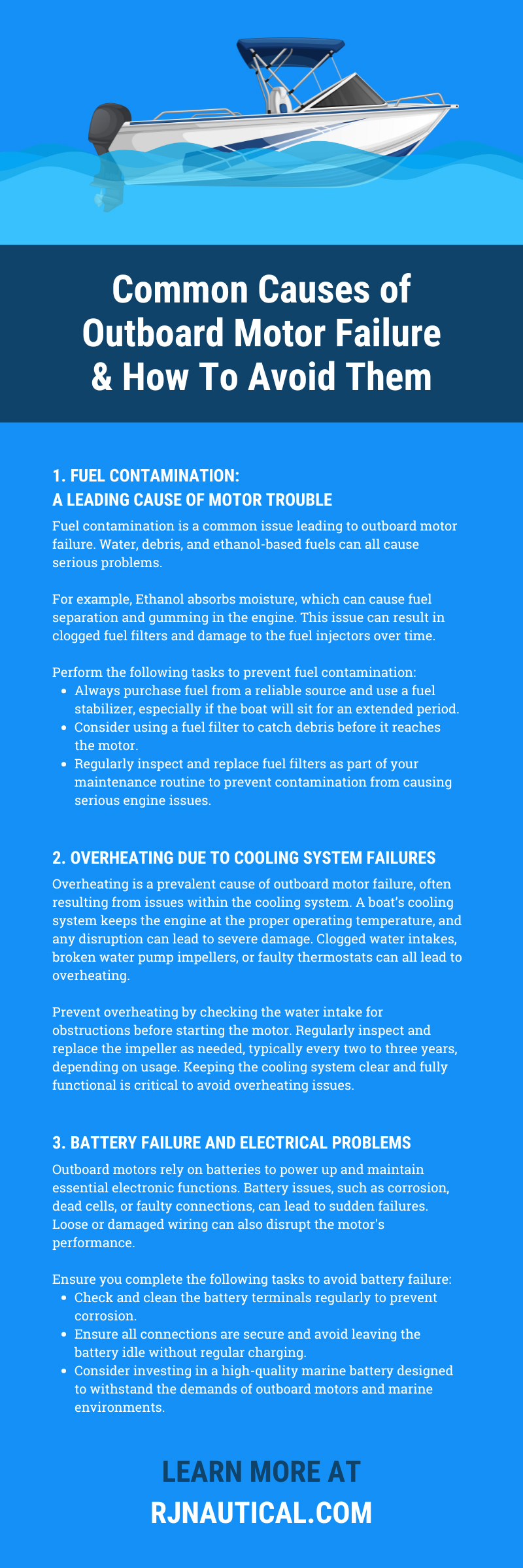

Common Causes of Outboard Motor Failure & How To Avoid Them

An outboard motor is the heart of your boating vessel, providing the power needed to navigate waters smoothly. However, like any engine, outboard motors are prone to certain issues, which can lead to costly repairs or, worse, leave you stranded.

Knowing the common causes of outboard motor failure and how to avoid them is essential for every boat owner. By understanding these issues and following preventative steps, you can keep your outboard motor running reliably for years.

1. Fuel Contamination: A Leading Cause of Motor Trouble

Fuel contamination is a common issue leading to outboard motor failure. Water, debris, and ethanol-based fuels can all cause serious problems.

For example, Ethanol absorbs moisture, which can cause fuel separation and gumming in the engine. This issue can result in clogged fuel filters and damage to the fuel injectors over time.

Perform the following tasks to prevent fuel contamination:

- Always purchase fuel from a reliable source and use a fuel stabilizer, especially if the boat will sit for an extended period.

- Consider using a fuel filter to catch debris before it reaches the motor.

- Regularly inspect and replace fuel filters as part of your maintenance routine to prevent contamination from causing serious engine issues.

2. Overheating Due to Cooling System Failures

Overheating is a prevalent cause of outboard motor failure, often resulting from issues within the cooling system. A boat’s cooling system keeps the engine at the proper operating temperature, and any disruption can lead to severe damage. Clogged water intakes, broken water pump impellers, or faulty thermostats can all lead to overheating.

Prevent overheating by checking the water intake for obstructions before starting the motor. Regularly inspect and replace the impeller as needed, typically every two to three years, depending on usage. Keeping the cooling system clear and fully functional is critical to avoid overheating issues.

3. Battery Failure and Electrical Problems

Outboard motors rely on batteries to power up and maintain essential electronic functions. Battery issues, such as corrosion, dead cells, or faulty connections, can lead to sudden failures. Loose or damaged wiring can also disrupt the motor's performance.

Ensure you complete the following tasks to avoid battery failure:

- Check and clean the battery terminals regularly to prevent corrosion.

- Ensure all connections are secure and avoid leaving the battery idle without regular charging.

- Consider investing in a high-quality marine battery designed to withstand the demands of outboard motors and marine environments.

4. Poor Lubrication and Oil Issues

Proper lubrication is vital to any engine’s health, including outboard motors. Low or poor-quality oil can lead to excessive wear on internal parts, causing the motor to seize. Sometimes, boat owners overlook regular oil checks, leading to oil sludge buildup or running the engine with low oil levels.

Prevent oil-related failures by using the manufacturer-recommended oil type and regularly checking the oil level. Change the oil and oil filter according to the recommended schedule in your outboard motor’s manual. Staying diligent with oil maintenance is an easy but crucial step in preventing motor failure.

5. Spark Plug Problems Affecting Engine Performance

Spark plugs are small yet essential components that ignite the fuel-air mixture in the engine. Over time, spark plugs can become worn, fouled, or even damaged, resulting in poor engine performance or a complete failure to start.

Inspect and replace spark plugs regularly, as specified in your motor’s maintenance schedule, to avoid problems. Clean around the spark plug area to prevent dirt and debris from entering the engine when replacing them. Keeping spark plugs in good condition ensures smooth engine operation and prevents unexpected breakdowns.

6. Improper Winterization Leading to Long-Term Damage

Failing to winterize your outboard motor properly can lead to significant problems, especially in colder climates where water left in the engine can freeze and expand, causing cracks and leaks. Additionally, leaving old fuel in the motor during the off-season can result in gumming and corrosion.

You can avoid these issues by thoroughly winterizing your outboard motor. Flush the engine with fresh water, add a fuel stabilizer to the tank, and drain any remaining water from the motor. Proper winterization protects your motor during the off-season, ensuring it’s ready when boating season returns.

7. Propeller Damage and Misalignment

A damaged or misaligned propeller can create vibrations that strain the outboard motor. Hitting submerged objects can damage the propeller, impacting performance and fuel efficiency. A bent or unbalanced propeller can also cause the motor to overheat and wear out faster.

Regularly inspect the propeller for any signs of damage or misalignment to combat this issue. Replace damaged propellers and balance them to prevent unnecessary strain on the motor. Regular propeller maintenance is essential to keeping your outboard motor running smoothly.

8. Ignition System Failures

The ignition system starts the motor and ensures it runs efficiently. Problems with the ignition coil, ignition switch, or wiring can lead to misfires or prevent the engine from starting. The ignition system might be at fault if you’re having trouble starting the motor.

Inspect the ignition components regularly and replace any faulty parts as needed. Ensure connections are secure and free from corrosion. Following routine checks for the ignition system can save you from inconvenient starts and costly repairs.

9. Carburetor Issues Affecting Fuel Delivery

Carburetor problems can lead to engine performance issues in outboard motors that rely on a carburetor rather than fuel injection. Over time, dirt and varnish from fuel can clog the carburetor, preventing the engine from getting the proper fuel mixture. This lack of fuel can result in rough idling, stalling, or complete failure.

Avoid carburetor problems by cleaning it regularly and using a fuel stabilizer. Consider having the carburetor professionally cleaned or rebuilt if you notice a clog or that it clogs easily. Proper carburetor maintenance ensures the motor receives the correct fuel mixture, enhancing performance and longevity.

10. Neglecting Regular Maintenance

Finally, a lack of regular maintenance is one of the leading causes of outboard motor failure. Skipping routine checks, ignoring minor issues, and delaying service can lead to bigger, more expensive problems. Outboard motors require routine care to function optimally, including regular inspections of filters, seals, belts, and hoses.

Stick to a maintenance schedule and consult your motor’s manual for specific guidelines. Regularly check for loose connections, replace worn-out parts, and promptly address minor issues. Taking proactive care of your motor is the best way to avoid unexpected breakdowns.

Understanding the common causes of outboard motor failure and how to avoid them can help you ensure your boat is always ready for a smooth trip. Addressing these problems will extend your motor’s life and enhance your boating experience, from fuel contamination and overheating to spark plug issues and neglected maintenance.

Yamaha Outboard dealers like RJ Nautical offer expertise and support to keep your motor in top condition. With our inventory of outboard motors, you can keep your boat operating at peak performance.