How To Diagnose Overheating Issues in Outboard Motors

Keeping your outboard motor in peak condition is essential for enjoying a smooth and safe time on the water. Overheating is one of the most common issues boat owners face, and it’s not something to take lightly. If left unchecked, it can cause costly damage to your engine and cut your boating adventures short. The following guide explores how to diagnose overheating issues in outboard motors, ensuring you can spot the warning signs early and act decisively.

Understand the Basics of Your Cooling System

It helps to understand how your outboard motor’s cooling system works to diagnose overheating issues effectively. Most outboard motors rely on a water pump-driven cooling system. As the motor runs, the impeller pulls in water from the lake or ocean and circulates it through the engine to absorb and dissipate heat. After cooling the engine, the water exits through the exhaust system.

There are a few critical components in this setup: the water intake, the water pump (with the impeller), the thermostat, and the exit port. Any blockage, malfunction, or wear in this chain can disrupt the cooling flow and lead to overheating. Salt, debris, or plant matter can clog the intake. A worn or damaged impeller may not circulate enough water. A thermostat stuck in the closed position can restrict flow entirely.

Boat owners must regularly inspect these components. Just like checking the oil or fuel levels, make it a habit to visually inspect the water intake ports and ensure they’re free of obstructions before every trip. Knowing the basic flow of your cooling system makes it easier to pinpoint issues when something goes wrong.

Recognize the Early Warning Signs of Overheating

Spotting the early signs of overheating can prevent you from getting stranded or damaging your motor. Many modern outboards have built-in sensors and alarms that alert you if temperatures climb too high. However, even without a warning system, there are physical signs you can spot.

A sudden drop in engine performance often accompanies overheating. You might notice your boat struggles to plane or that throttle response lags. Unusual sounds like knocking or pinging can also indicate temperature stress. If steam rises from the engine or the cowling feels hotter than normal to the touch, you’re likely dealing with an overheating issue.

Pay attention to the telltale stream coming from the engine’s cooling water outlet. A weak or absent stream can signal an issue with water flow, which often leads to overheating. If the water exiting the telltale is too hot to touch or has stopped altogether, shut down the motor and investigate further.

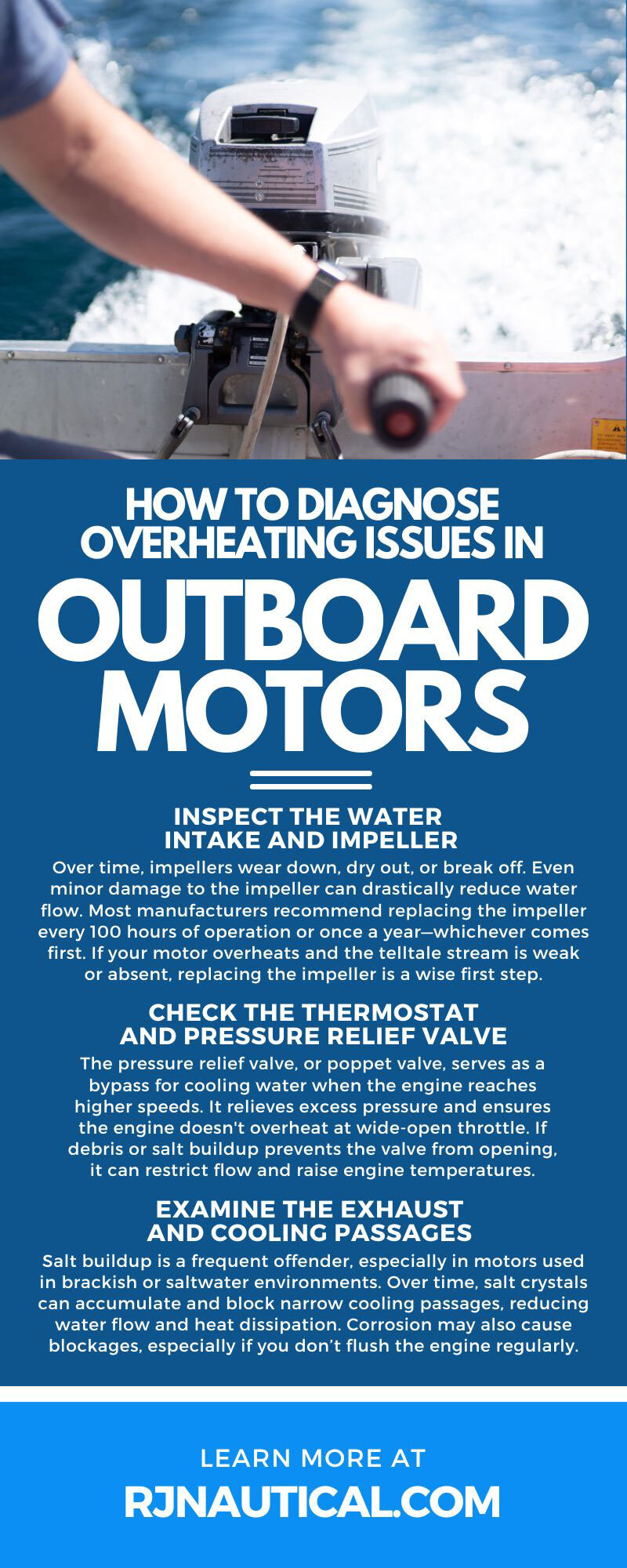

Inspect the Water Intake and Impeller

One of the first places to look when dealing with overheating is the water intake system. The intake ports, located at the bottom of the motor’s lower unit, must stay clear of debris. Sand, grass, or debris in the water can block these ports and restrict water flow to the impeller.

Once you've confirmed the intake is clear, the impeller is the next critical part to examine. This small rubber component is essential for pulling water through the system. It sits inside the water pump housing and rotates at high speeds to circulate coolant.

Over time, impellers wear down, dry out, or break off. Even minor damage to the impeller can drastically reduce water flow. Most manufacturers recommend replacing the impeller every 100 hours of operation or once a year—whichever comes first. If your motor overheats and the telltale stream is weak or absent, replacing the impeller is a wise first step.

Check the Thermostat and Pressure Relief Valve

Once you've ruled out blockages and the impeller, focus on checking the thermostat and pressure relief valve. These components regulate engine temperature by controlling how much water flows through the motor at any time.

The thermostat opens and closes based on the engine's temperature. If it sticks shut, water can't circulate properly, and the engine overheats. Remove the thermostat and test it by placing it in hot water. It should open at the temperature specified by your engine’s manual, usually around 143°F (62°C). If it stays closed, replace it.

The pressure relief valve, or poppet valve, serves as a bypass for cooling water when the engine reaches higher speeds. It relieves excess pressure and ensures the engine doesn't overheat at wide-open throttle. If debris or salt buildup prevents the valve from opening, it can restrict flow and raise engine temperatures.

These parts often get overlooked in routine maintenance but can significantly impact cooling efficiency. If you're experiencing overheating at high speeds but not while idling, you may have a faulty poppet valve. Cleaning or replacing these components is usually a straightforward task and can restore normal function quickly.

Examine the Exhaust and Cooling Passages

If the water pump, thermostat, and intake function correctly but the motor still overheats, the problem may lie deeper within the engine, specifically in the internal cooling and exhaust passages.

Salt buildup is a frequent offender, especially in motors used in brackish or saltwater environments. Over time, salt crystals can accumulate and block narrow cooling passages, reducing water flow and heat dissipation. Corrosion may also cause blockages, especially if you don’t flush the engine regularly.

Inspect the exhaust passages and the area around the cylinder head. Carbon buildup or deposits from burnt exhaust gases can also restrict water flow in these areas. Some motors may require disassembly or a flush with a specialized descaling solution to restore proper circulation.

Routine flushing after every trip, particularly in saltwater, can prevent these issues before they start. Use freshwater flush kits or earmuffs to rinse the engine thoroughly. If you suspect an internal blockage, consider hiring a boat mechanic to perform a chemical flush or inspect the engine's internal parts.

Maintain a Routine Inspection Schedule

The best way to avoid overheating issues is through consistent, proactive maintenance. Engines give plenty of warning signs before serious damage sets in, but only if you’re paying attention. You should always keep a maintenance log and follow the schedule recommended by your engine manufacturer.

Every time you take your boat out, visually check the water intake screens and confirm the telltale stream is strong and consistent. Monthly, inspect the condition of the cooling hoses, clamps, and impeller housing. Annually, replace the impeller, thermostat, and flush the entire cooling system—more often if you frequently drive your boat in saltwater.

Additionally, stay stocked with spare parts such as impellers, thermostats, and gaskets. These components are inexpensive compared to the cost of a rebuild or replacement engine. Boat owners who take maintenance seriously tend to get the longest life and best performance out of their motors.

Diagnose and Resolve Complex Cooling System Issues

Learning how to diagnose overheating issues in outboard motors is an essential skill every boat owner should develop. From checking the impeller and thermostat to clearing blocked water passages, these inspections help you stay ahead of problems before they become major issues.

If you’re having trouble with your engine and you’ve run through the basic diagnostics, don’t hesitate to contact certified professionals. The Yamaha outboard dealers from RJ Nautical have the tools and expertise to diagnose and resolve complex cooling system issues.